In practice: making a pressed pellet

The following figure shows the complete process from sample preparation to pressing.

After grinding 4 g of sample with 1 g of binder (e.g. CEREOX®) is mixed. Before pressing, the press tool can be lined with pellet film, which prevents subsequent sticking, makes cleaning easier and prevents contamination of the pressed pellet by the hardened steel ( Cr , Fe ). Aluminum cups can help a pellet to stabilize and enable easy labeling, but otherwise have no other use.

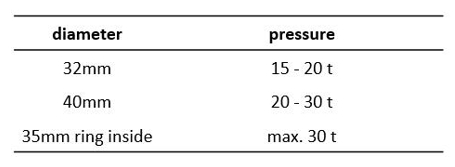

The following table gives empirical values for the required pressing pressure depending on the diameter of a pressed pellet. The rule here is that the pressing must be reproducible, i.e. the same density is always achieved in the pressed pellet. Direct pressing from 0 to 30 tons, for example, can prevent the air contained in it from escaping quickly enough. This then leads to flaking on the pellet. Here it is recommended to use a smaller pressure or to divide the pressing process into several steps.